WPC architrave, also known as wood-plastic composite skirting or composite trim, has become an increasingly popular choice in construction and interior design due to its durability, moisture resistance, and aesthetic versatility. But how exactly is this innovative material manufactured? The process involves a sophisticated blend of material science and engineering, transforming raw components into the finished profiles we see adorning doorways and windows.

Raw Materials: The Foundation of WPC Architrave

The journey of WPC architrave begins with its core constituents: wood fibers and thermoplastic polymers.

-

Wood Fibers: These typically come from recycled wood sources such as sawdust, wood chips, and agricultural waste. The quality and type of wood fiber significantly influence the final product's strength and appearance. Before use, the wood fibers are usually dried to a specific moisture content and often ground into a fine powder to ensure uniform dispersion within the polymer matrix.

-

Thermoplastic Polymers: The most common polymers used are polyvinyl chloride (PVC) or polyethylene (PE). These plastics provide the binding agent, encapsulating the wood fibers and giving the composite its shape, water resistance, and processability.

-

Additives: A crucial element in WPC manufacturing, additives enhance various properties of the final product. These can include:

-

Coupling Agents: These chemicals improve the bond between the hydrophobic polymer and hydrophilic wood fibers, leading to better mechanical properties and reduced water absorption.

-

Stabilizers: Heat and UV stabilizers protect the material from degradation during processing and extend its lifespan when exposed to sunlight.

-

Lubricants: These aid in the smooth flow of the molten material during extrusion, improving surface finish and reducing wear on machinery.

-

Pigments: Used to achieve desired colors, mimicking natural wood tones or providing a range of decorative options for the WPC door frame molding.

-

Foaming Agents: In some cases, these are added to create a cellular structure, reducing the material's density and weight while improving insulation properties.

-

The Manufacturing Process: Extrusion at Its Core

The primary method for manufacturing WPC architrave is extrusion, a continuous process that shapes the molten composite material into a desired profile.

-

Mixing and Compounding: The carefully measured raw materials—wood fibers, thermoplastic polymers, and various additives—are first thoroughly mixed in high-intensity blenders. This ensures a homogeneous blend, crucial for consistent product quality. The mixture is then often compounded, which involves melting and blending the materials in an extruder to create pellets or granules. This pre-compounding step further enhances the dispersion of ingredients and can improve the consistency of the final extrusion process.

-

Extrusion: The compounded material or direct mixture is fed into a specialized extruder, typically a twin-screw extruder for WPC. Inside the extruder, heating elements melt the polymer, and the rotating screws knead and convey the molten composite towards a die. The design of the screws is critical for proper mixing, melting, and devolatilization (removal of trapped gases).

-

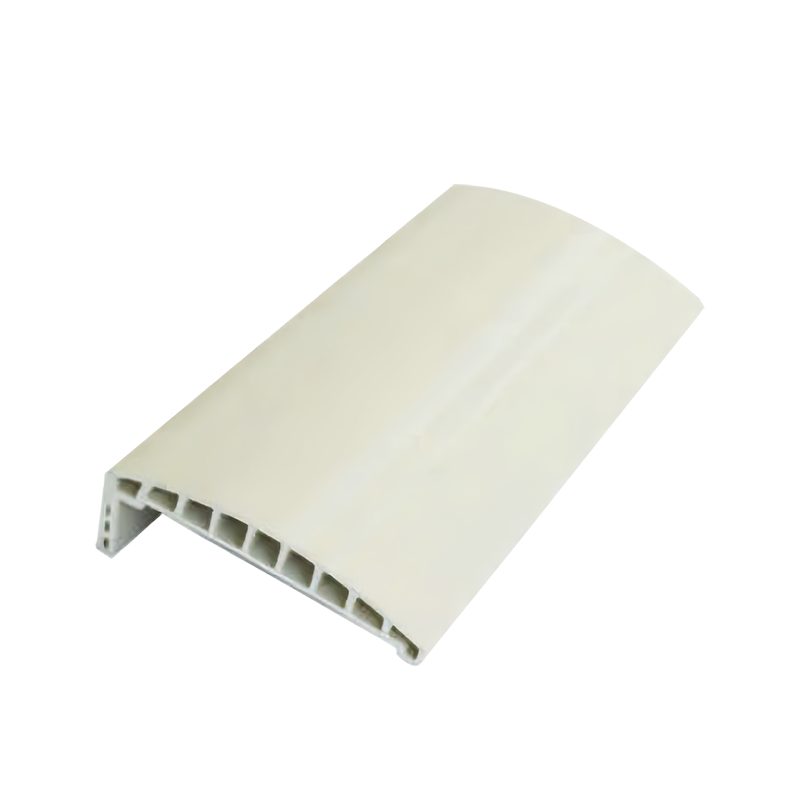

Die Forming: As the molten WPC exits the extruder, it is forced through a precisely shaped die. The die dictates the final profile of the WPC skirting board, whether it's a flat architrave, a decorative molding, or a specific WPC trim design. The temperature of the die is carefully controlled to ensure a smooth surface finish and accurate dimensions.

-

Calibration and Cooling: Immediately after exiting the die, the hot WPC profile enters a calibration unit. This typically involves vacuum sizing, where a vacuum draws the profile against cooled metal plates, helping it to maintain its precise shape and dimensions as it cools and solidifies. Water baths or air cooling systems are used to progressively cool the profile. Rapid and uniform cooling is essential to prevent warping and ensure dimensional stability.

-

Haul-off and Cutting: Once sufficiently cooled and rigid, the continuous WPC profile is pulled by a haul-off unit at a controlled speed. This unit ensures a consistent pull, preventing stretching or compression of the material. Finally, a cutting saw automatically cuts the continuous profile into pre-determined lengths, ready for packaging and distribution.

Quality Control: Ensuring Performance and Aesthetics

Throughout the manufacturing process, stringent quality control measures are implemented to ensure the WPC architrave meets the required standards. This includes:

-

Material Testing: Verifying the quality and composition of incoming raw materials.

-

In-process Monitoring: Continuously checking extrusion parameters such as temperature, pressure, and screw speed.

-

Dimensional Accuracy: Regularly inspecting the dimensions and straightness of the extruded profiles.

-

Mechanical Property Testing: Conducting tests for flexural strength, impact resistance, and screw withdrawal resistance.

-

Water Absorption and Swelling Tests: Assessing the material's resistance to moisture.

-

Color Consistency and Surface Finish: Visually inspecting for defects, color uniformity, and smooth finishes.

By combining carefully selected raw materials with precise extrusion technology and rigorous quality control, manufacturers are able to produce high-performance WPC architrave that offers an attractive and durable alternative to traditional wood or plastic trims. Its ease of installation and low maintenance requirements further solidify its position as a preferred choice in modern construction.