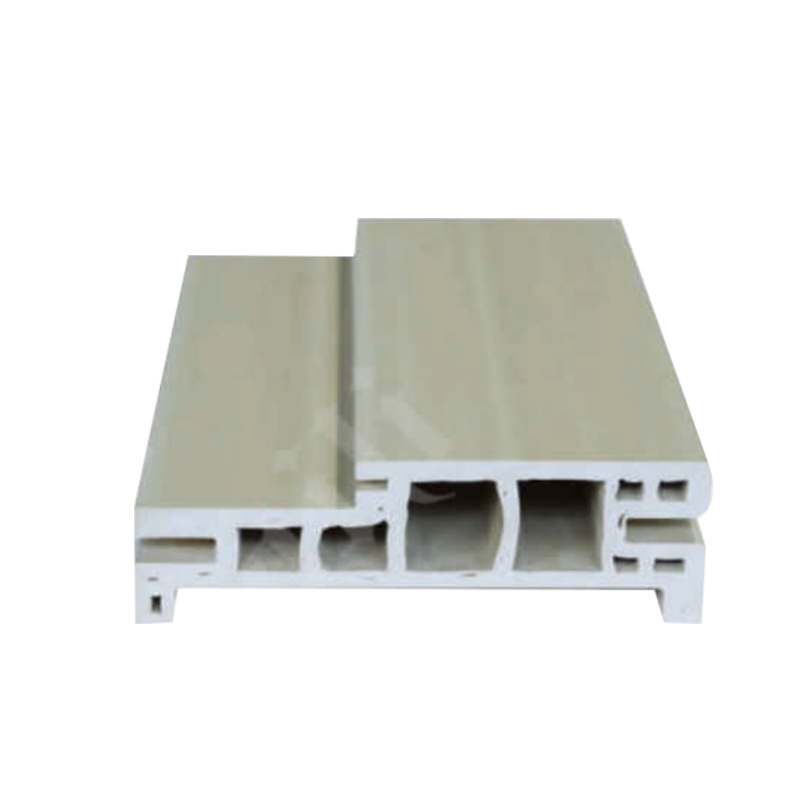

A WPC frame, or Wood-Plastic Composite frame, represents a significant innovation in construction and design, offering a sustainable and high-performance alternative to traditional materials like solid wood, pure plastics, and metals. WPC is a hybrid material composed of wood fibers or wood flour and thermoplastic(s) (e.g., polypropylene, polyethylene, PVC), often with the addition of various additives such as coupling agents, UV stabilizers, colorants, and lubricants. These components are carefully blended and processed, typically through extrusion, injection molding, or compression molding, to create a material that combines the best characteristics of both wood and plastic.

Composition and Manufacturing Process

The core of a WPC frame lies in its unique composition:

-

Wood Content: This typically ranges from 30% to 70% by weight and can be sourced from recycled wood waste, sawdust, wood chips, or even bamboo. The wood fibers provide stiffness, strength, and a natural aesthetic.

-

Plastic Content: Thermoplastics bind the wood fibers together and impart water resistance, durability, and ease of processing. The choice of plastic influences the final properties of the WPC.

-

Additives: These are crucial for enhancing various properties:

-

Coupling agents: Improve the bond between the hydrophilic wood and hydrophobic plastic.

-

UV stabilizers: Protect the material from degradation due to sunlight exposure.

-

Colorants: Allow for a wide range of aesthetic options.

-

Lubricants: Aid in processing and improve surface finish.

-

Foaming agents: Can be used to reduce density and weight.

-

The manufacturing process usually involves:

-

Mixing: Raw materials are thoroughly mixed to ensure a homogenous blend.

-

Compounding/Pelletizing: The mixture is heated and processed into pellets.

-

Extrusion/Molding: The pellets are then melted and forced through a die (extrusion) to form continuous profiles, or injected into molds (injection molding) to create specific shapes, or pressed into forms (compression molding).

-

Cooling and Finishing: The formed WPC is cooled and then cut, sanded, or treated as required.

Key Characteristics and Advantages

WPC frames offer a compelling set of advantages that make them suitable for a wide array of applications:

-

Durability and Longevity: They are highly resistant to rot, decay, and insect infestation, unlike traditional wood. Their plastic content provides excellent water resistance, making them ideal for outdoor and high-moisture environments.

-

Low Maintenance: WPC frames do not require painting, staining, or sealing, significantly reducing maintenance efforts and costs over their lifespan. They are also easy to clean.

-

Weather Resistance: They exhibit good resistance to harsh weather conditions, including UV radiation, extreme temperatures, and moisture fluctuations, minimizing warping, cracking, or splintering.

-

Dimensional Stability: WPC is less prone to expansion and contraction due to moisture or temperature changes compared to solid wood, leading to greater stability in structures.

-

Sustainability: Many WPC products utilize recycled wood and plastic, contributing to waste reduction and sustainable resource management. They can also be recyclable at the end of their life cycle.

-

Aesthetic Versatility: WPC can be manufactured in various colors, textures, and finishes, often mimicking the look and feel of natural wood, providing design flexibility.

-

Workability: WPC frames can be cut, drilled, nailed, and fastened using standard woodworking tools, simplifying installation.

-

Safety: They are typically splinter-free and can be formulated with slip-resistant surfaces, enhancing safety in applications like decking.

Applications of WPC Frames

The versatility of WPC frames has led to their widespread adoption across numerous sectors:

-

Window and Door Frames: Their excellent weather resistance and dimensional stability make them an ideal choice for durable and low-maintenance window and door frames, particularly in areas exposed to moisture.

-

Decking and Railing Systems: This is one of the most common applications, owing to WPC's resistance to rot, splinters, and the need for frequent sealing.

-

Fencing: WPC fences offer durability and a long lifespan with minimal upkeep.

-

Outdoor Furniture: Their weather resistance ensures longevity and reduces maintenance for chairs, tables, and benches.

-

Cladding and Siding: WPC provides an attractive and durable exterior finish for buildings.

-

Pergolas and Gazebos: Their structural integrity and weather resistance make them suitable for outdoor leisure structures.

-

Interior Applications: Increasingly, WPC is used for interior door frames, skirting boards, and decorative trims due to its moisture resistance and ease of cleaning.

-

Marine Applications: In some cases, WPC is used for boat decking or dock components due to its water resistance, though specialized marine-grade composites are often preferred for critical structural elements.

Conclusion

In summary, a WPC frame is a modern engineered material that effectively bridges the gap between traditional wood and plastic, offering a superior combination of aesthetics, durability, and low maintenance. Its eco-friendly profile, coupled with its resistance to the common challenges faced by wood, positions WPC as a leading material for a diverse range of construction and design applications, contributing to more sustainable and long-lasting structures.