What is Melamine Paper and Why Does Size Matter?

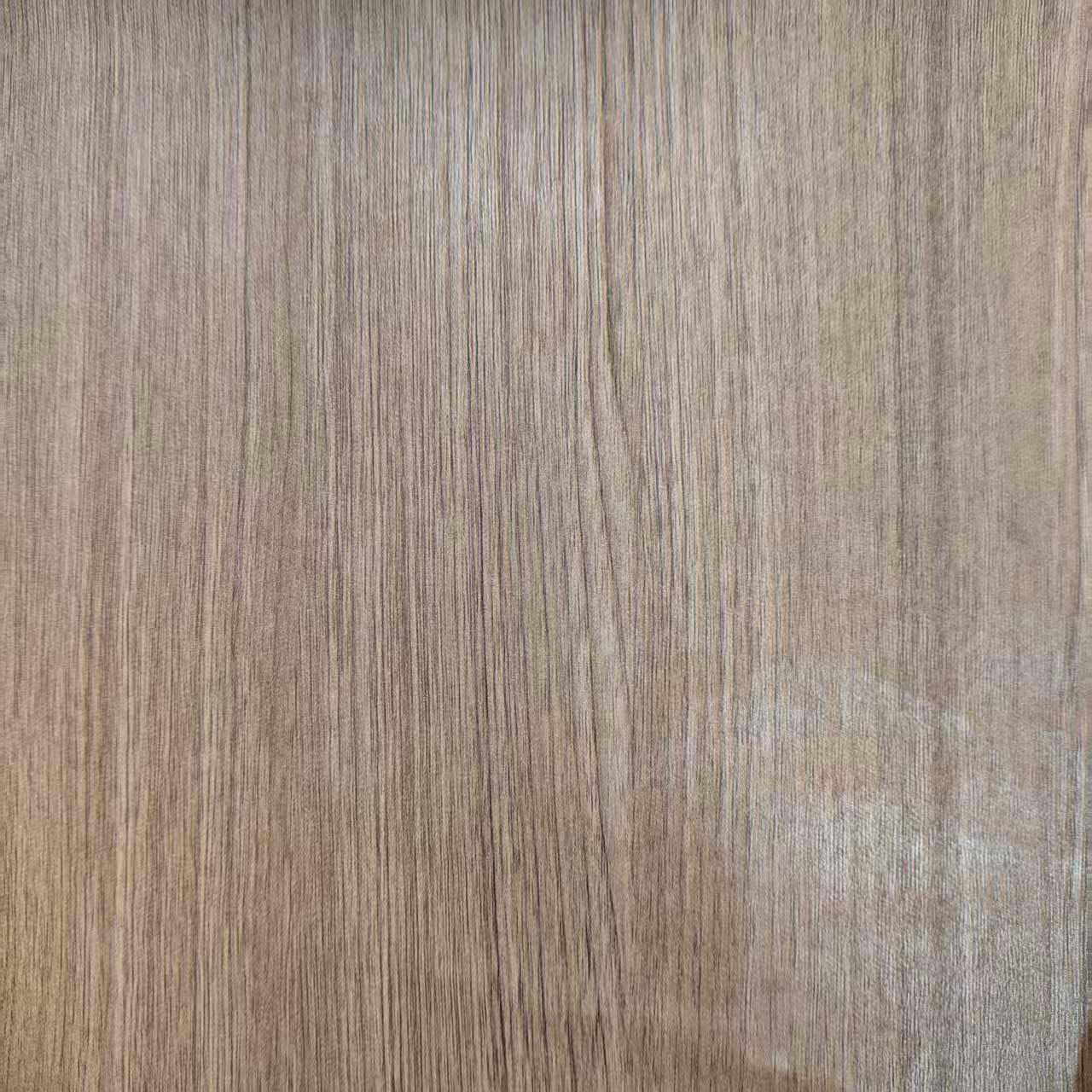

Melamine paper, often simply called decorative paper, is a key component in the production of laminates and veneered panels used in furniture, flooring, and interior design. At its core, it’s a specialty paper printed with a decorative design (like wood grain, solid color, or abstract pattern) that is impregnated with a thermosetting resin, primarily melamine-formaldehyde resin.

When subjected to high pressure and heat, this resin-soaked paper melts and cures, forming a rock-hard, durable, scratch-resistant, and moisture-resistant surface layer. This process is how everyday items like kitchen countertops, laminate flooring, and office desks get their tough, attractive finish.

The keyword, Wide Sized Melamine Paper, refers to a specialized product within this industry. As manufacturing processes for wood panels (like MDF and particleboard) have trended toward larger, seamless sheets to reduce waste and assembly time, the demand for wider decorative papers has grown. Traditional paper widths might require multiple sheets or careful alignment, but wider rolls allow manufacturers to cover an entire panel with a single sheet of decorative paper, ensuring a perfect, uniform look and streamlining production.

From Wood Pulp to Durable Design: The Manufacturing Journey

The journey of melamine paper begins with a highly absorbent, high-quality base paper.

The Printing Stage: Where the Look is Created

This base paper is first fed through large industrial rotogravure printers. These are similar to newspaper presses but designed for extremely fine detail and precise color matching. Wood grain designs, for example, are meticulously reproduced using engraved rollers to achieve a realistic texture and depth of color. The quality of this printing is crucial, as it provides the aesthetic appeal of the final product.

The Impregnation Stage: The Resin is the Secret

Once the paper is printed, it is passed through a bath of liquid melamine-formaldehyde resin. This resin is a clear, viscous liquid. The process is known as impregnation, and it’s where the paper gains its superpowers. The resin penetrates every fiber of the paper.

Following the bath, the paper is moved through a long, high-temperature oven where excess solvent is flashed off, and the resin is partially cured, leaving the paper dry but still slightly tacky. At this point, the paper is not yet a laminate; it’s a semi-cured product that is stable and can be rolled and stored. This is the stage where the Wide Sized Melamine Paper is prepared for its final destiny—the laminating press.

The Pressing Matter: Creating the Final Product

The true transformation happens when the impregnated paper is laid onto a substrate (like a particleboard panel) and pressed.

High-Pressure Laminate (HPL) vs. Low-Pressure Laminate (LPL)

There are two main applications for melamine paper:

- Low-Pressure Laminate (LPL) or Melamine Faced Chipboard (MFC): This is the most common application where the wide-sized melamine paper is directly pressed onto a wood panel (like particleboard or MDF). The press operates at a lower pressure and for a shorter duration. The result is a finished board perfect for cabinets, shelving, and furniture.

- High-Pressure Laminate (HPL): Here, multiple layers of phenolic resin-soaked kraft paper are pressed together first, and the melamine paper is used as the top layer. This creates an extremely durable, thick, self-supporting sheet that is later glued onto a substrate.

In both cases, the heat and pressure activate the remaining resin, causing it to cross-link and polymerize fully. The paper essentially turns into a rigid, plastic-like sheet that is chemically bonded to the panel below. This is what provides the finished surface with its unparalleled resistance to scratches, heat, and household chemicals.

Environmental and Economic Impact

Melamine paper technology offers significant advantages over using natural materials:

- Sustainability: It reduces the reliance on real wood veneers and solid wood, allowing manufacturers to use rapidly renewable, engineered wood products (like MDF) as the core, promoting efficient use of forest resources.

- Consistency and Cost: It allows for perfectly consistent colors and patterns across millions of panels, something impossible with natural wood. Furthermore, it is a far more economical way to achieve premium looks, making high-end aesthetics accessible to the mass market.

- Durability: The inherent toughness of the melamine surface means the finished products last longer and require less maintenance than many traditional finished wood surfaces.

The use of Wide Sized Melamine Paper continues to drive innovation in the furniture and construction industries, making modern, durable, and attractive surfaces the standard in homes and businesses across the globe.