What is Melamine Decorative Paper?

Melamine decorative paper is an unsung hero in modern interior design and furniture manufacturing. Chances are, you interact with products made using this material every single day, from your kitchen cabinets and office desks to laminate flooring and retail display shelves.

Simply put, it’s a specialized paper that has been printed with a decorative design (like a wood grain, stone pattern, or a solid color) and then impregnated with melamine-formaldehyde resin. This resin is the key to its magic, transforming the paper from a fragile sheet into a hard, durable, and chemically resistant surface when it is pressed onto a core material like particleboard or Medium-Density Fiberboard (MDF).

The Making of a Durable Surface

The production of melamine decorative paper involves a precise, multi-step process that ensures both its aesthetic quality and its incredible toughness.

1. The Raw Paper

The process starts with a high-quality, specialized raw paper. This paper is highly porous, which allows it to absorb the resin evenly. It’s often referred to as “base paper” or “decor paper” and is typically manufactured to have a consistent color and fiber structure.

2. Printing the Design

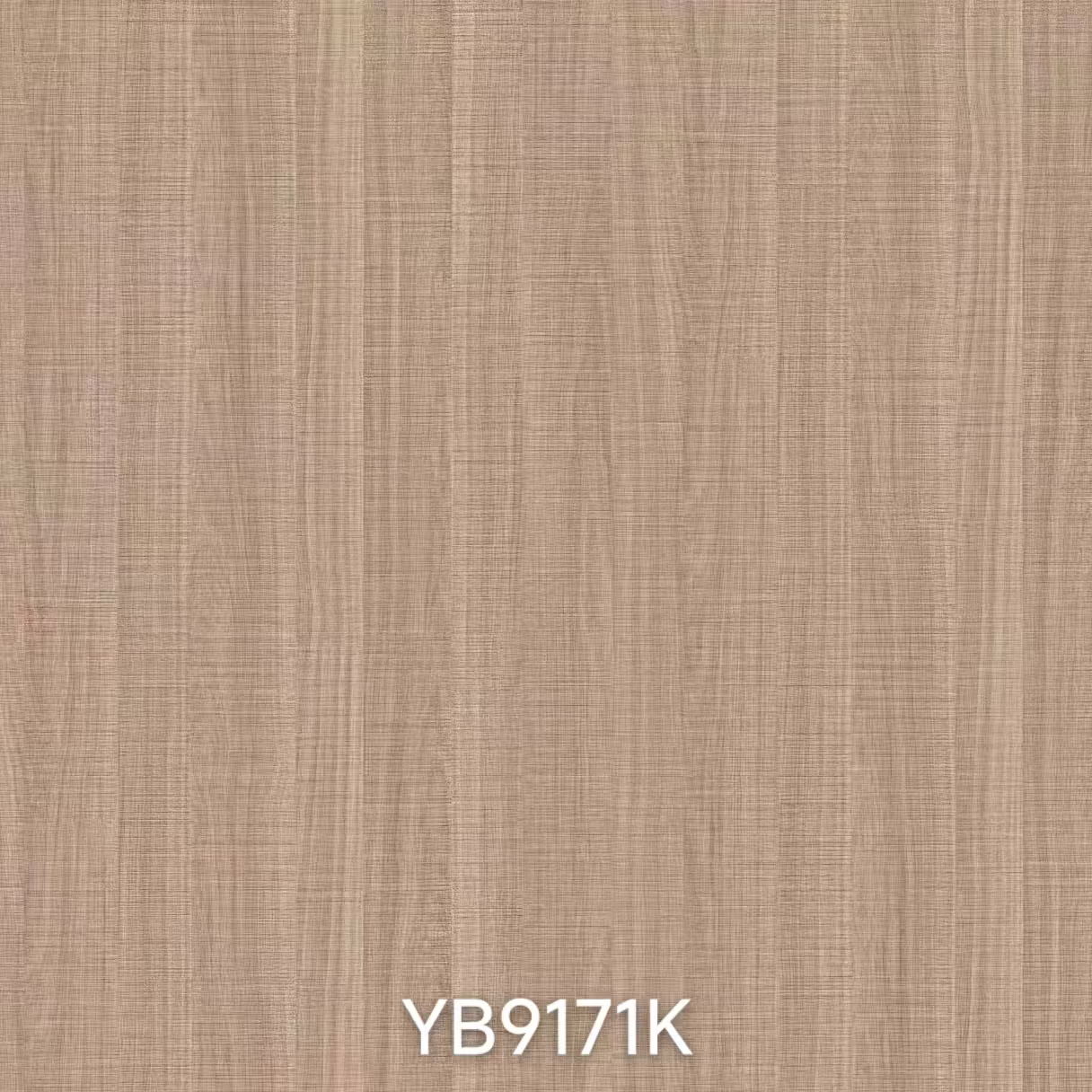

Next, the base paper is fed into large-scale gravure printing machines. These machines use engraved cylinders to transfer intricate patterns—like the realistic knots and grain of oak or the subtle veining of marble—onto the paper with high-quality inks. The fidelity of these prints is what makes modern laminates so difficult to distinguish from real wood or stone.

3. Impregnation and Curing (The Melamine Magic)

This is the most critical step. The printed paper is run through an impregnator, where it is soaked with a solution containing the melamine-formaldehyde resin. The resin is a clear liquid that penetrates the paper’s fibers.

The paper is then dried in a controlled oven. This drying process doesn’t fully cure the resin; it only dries it to a specific, partially cured state known as the B-stage. At this stage, the paper is dry to the touch and can be stored and handled, but the resin is still waiting to be fully activated by heat and pressure.

4. Pressing and Bonding

The resin-impregnated paper is placed over a core panel (usually particleboard or MDF). This assembly is then put into a large hot press. Under immense heat (around $170^\circ\text{C}$) and pressure (up to 300 to 500 PSI), the following happens:

- The B-stage melamine resin flows, chemically bonding the decorative paper permanently to the core material.

- The resin fully cures, or polymerizes, hardening into a rigid, plastic-like sheet that creates the final, highly durable surface.

Why is Melamine So Popular? (The Benefits)

The popularity of melamine decorative paper stems from its balance of performance, affordability, and versatility.

- Cost-Effectiveness: It provides the look of expensive materials (like exotic woods or granite) at a fraction of the cost of the real thing.

- Durability and Wear Resistance: The fully cured melamine surface is highly resistant to scratches, abrasion, and minor impacts, making it excellent for high-traffic areas.

- Moisture and Stain Resistance: Melamine creates a sealed surface that is non-porous. This makes it easy to clean and resistant to most common household chemicals and stains.

- Design Versatility: Because the design is printed, there are virtually unlimited color, pattern, and texture options available, allowing designers to achieve any aesthetic.

- Consistency: Unlike natural materials, the color and pattern of melamine paper are perfectly uniform across large sheets, which is essential for large-scale furniture and cabinetry projects.

Melamine Decorative Paper vs. Laminate

The terms “melamine” and “laminate” are often used interchangeably, but there’s a technical difference:

- Melamine Decorative Paper (Direct Laminate): This refers to the single sheet of resin-impregnated paper pressed directly onto a substrate like particleboard. The resulting product is often called Thermally Fused Laminate (TFL) or sometimes “melamine board.” It’s generally used for vertical surfaces and lower-wear applications like cabinet boxes and shelving.

- High-Pressure Laminate (HPL): This is a much thicker, multi-layer product made by pressing several sheets of resin-soaked kraft paper together before the decorative melamine layer is added to the top. HPL is significantly tougher and more impact-resistant, making it ideal for kitchen countertops and commercial surfaces.

In both cases, however, the final aesthetic and protective layer that you see is thanks to that beautiful, durable melamine decorative paper.